Centricast® Pipes: A Comparative Guide to CL, RB, and Z-Core FRP Solutions for Industrial Applications

Introduction: Centricast® Pipes: Robust FRP Solutions for Demanding Industrial Environments

Centrifugally cast FRP (fiberglass reinforced plastic) pipes, marketed under the Centricast® brand, are engineered to deliver high performance, corrosion resistance, and durability in extreme industrial environments. These pipes are widely used in chemical processing, power generation, mining, and wastewater treatment facilities due to their superior material properties and reliability. The Centricast® product line consists of three specialized variants—CL, RB, and Z-Core—each designed to meet specific operational demands. This blog explores their core features, benefits, and ideal applications, followed by a comparative table to help decision-makers select the most suitable pipe type.

Product Overviews:

Centricast® CL

- Built with high-strength glass fabrics and corrosion-resistant vinyl ester resin.

- CL-1520: 50 mil pure resin corrosion barrier

- CL-2030: 100 mil pure resin corrosion barrier for enhanced protection

- Maximum temperature: 200°F (93°C)

- Applications: pharmaceutical plants, chemical processing systems, chlorine and strong oxidizers

Centricast® RB

- Built with high-strength glass fabrics and corrosion-resistant, temperature-resistant aromatic amine cured epoxy resin.

- RB-1520: 50 mil pure resin corrosion barrier

- RB-2530: 100 mil pure resin corrosion barrier for higher durability

- Maximum temperature: 250°F (121°C)

- Applications: Steel pickling, steam condensate return, power plants, chemical processing facilities, mining environments, hydrometallurgy

Centricast® Z-Core

- Built with high-strength glass fabrics and a premium, proprietary novolac epoxy resin.

- Designed with a 100 mil resin-rich liner.

- Offers resistance to aggressive chemicals, solvents and concentrated acids, including 98% sulfuric acid.

- Maximum temperature: 275°F (135°C)

- Applications: Advanced chemical processing, industrial waste lines, high-acid transport systems, solvents, hydrometallurgy, acidic slurries, steam condensate return

Common Applications

- Chemical Processing: Transport of caustic and acidic media

- Power Generation: Cooling and process lines resistant to heat and chemicals

- Mining Operations: Abrasive and chemically harsh slurry handling

- Wastewater Treatment: Corrosion-prone fluid transport

Key Advantages

- Superior Chemical Resistance: Designed to withstand acids, alkalis, and solvents

- Wide Temperature Range: Operates efficiently in environments up to 275°F

- Lightweight and Durable: Easy installation with reduced long-term maintenance

- High Performance: Ideal for demanding, continuous-use industrial pipelines

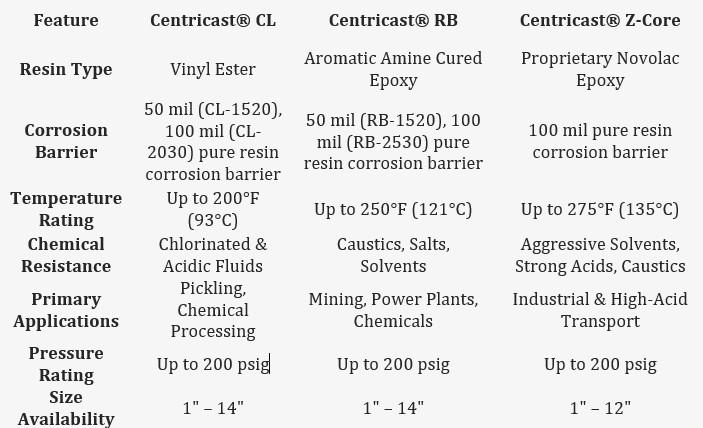

Centricast® Pipe Comparison Table

Conclusion

The Centricast® family of FRP pipes offers specialized solutions for industries that demand durability, high performance, and resistance to severe chemical environments. Whether you're transporting acidic mixtures or caustic slurries at elevated temperatures, there's a Centricast® pipe built for the task.

Explore more about each product here: